Since the admission by TEPCO that the plant has been leaking for the last 2+ years and that it continues to leak, there has been much international concern. Daiichi has massive amounts of groundwater passing through the plant grounds every day. The ground water is seeping into the reactor buildings and is becoming contamination with radioactive contamination. This is something no other nuclear site has had to deal with related to contamination or a meltdown. Fukushima differs greatly from both Hanford and Chernobyl, the two sites most frequently compared to the problem in Japan.

Water Bypass

TEPCO’s plan for a groundwater bypass is inadequate. It is too close to the reactors and has left the diversion wells contaminated. It also lacks the volume needed to effectively deal with the incoming groundwater. TEPCO has been unable to use these diversion wells due to the contamination yet continued with the construction of the underground wall at the sea front and solidifying soil in the same area. Was anyone surprised when water began backing up into the plant grounds?

What is needed is a far wider scale civil engineering project. This issue is not a mere problem with the local fishermen, it is an international problem. The Pacific is an international resource, Fukushima Daiichi is heavily polluting that resource on a daily basis and must be stopped sooner rather than later.

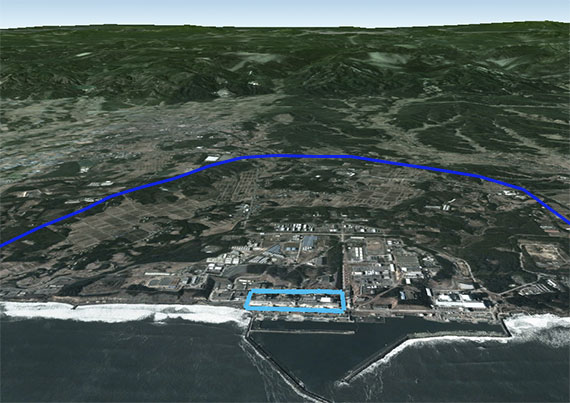

A larger groundwater diversion program that goes further inland, pumps up groundwater and routes it safely to the sea could be one potential solution. In our review of topographic maps of the area we found a number of candidate areas where groundwater diversion wells could be dug. Wells could be located in an arc around the plant grounds. Water could be routed using traditional water transport methods such as above or below ground piping or concrete canal systems. Contained systems would have the benefit of preventing any surface contamination from draining into the diversion water. In a larger diversion system such as this, pumping could be adjusted to slow the groundwater flow towards the plant to prevent leaking to the sea or flooding the plant while allowing enough groundwater to stay in the area to prevent ground subsidence. The map below shows potential locations for diversion wells. It should be possible to also place pipes along the same arc to route groundwater to the sea.

Another effort that would improve the effectiveness of bypass wells would be to install an underground sheet wall system, downstream from the diversion wells. A full or partial wall system could aid in the diversion process.

Along with this larger diversion project, the current underground wall being installed in the port should be completed as should the ground freezing effort already being planned. This water diversion project is a large scale civil engineering project and would take the efforts of experts in the field and construction companies skilled in such large projects to work properly.

It should not be left to TEPCO to conduct the work. There does exist the potential for unforeseen consequences of diverting large volumes of ground water. Any system should be established so the flow or stoppage of groundwater can be changed easily. The system should have the capability of returning to the original groundwater flow if new problems from the diversion show up. Geologists and civil engineers should be involved in the project and the day to day monitoring of the changes created by water diversion. Too much water removal could create unexpected pressures from the sea on structures at the plant, ground subsidence and other problems.

The Port

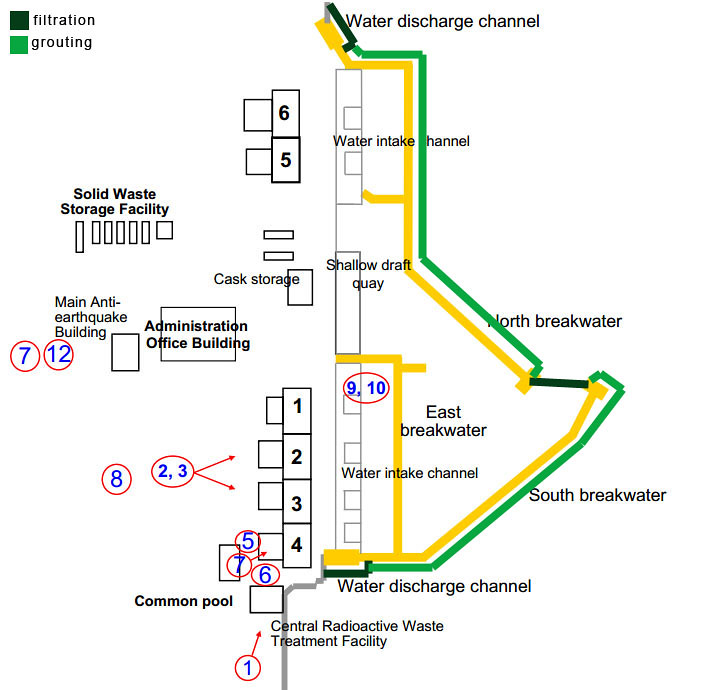

Some additional efforts will still be needed to assure more contamination is not leaking out to sea. The port should be blocked off or at a minimum, filtered. TEPCO has installed a silt fence and a fish net, this is not sufficient. Port containment could be done by blocking the port entrance and the discharge canals. We were unable to obtain documentation on the port walls themselves. If they are permeable they need to be concrete grouted over with a product such as a fibrous impregnated hydro-cement to help prevent more contaminated water from leaving the port. If the port walls are solid they should still be checked for breakage and leaks and the same cement treatment done to block any openings.

The port openings and discharge canals could be filtered with a mix of charcoal & zeolite placed in the openings as was attempted at the intake canals earlier on. If this is not practical or possible these openings should be completely closed to prevent further leakage from the plant.

Drainage And Groundwater

TEPCO has admitted that the plant’s water runoff system has never been blocked off or otherwise modified since the disaster. This has provided a route for any surface and sub surface contamination to be transported directly to the Pacific. Where possible these systems should be blocked off. The challenge created is that without water runoff capability the plant grounds may flood during heavy rain or in spring. Allowing the plant to freely discharge contaminated water is also an unacceptable problem. Too the extent the system has to remain functional efforts should be made to lower the amount of runoff and provide at a minimum charcoal and zeolite type filtration before it exits the plant to lower the contamination levels. While this is an imperfect solution, it is unlikely the plant can find room for even more water storage with the majority of the water storage tanks now found to potentially leak.

One option that should be explored for groundwater handling is an

underground filtration wall created by University of Buffalo researchers. This underground filtration wall is being tested to deal with radioactive groundwater at a defunct nuclear site in New York state. Clinoptilolite zeolite was found to be effective in filtering out strontium 90 in their test runs.

Alternative Solution: Utilize The Groundwater Pressure

The current situation in Daiichi is characterized, as anticipated from the beginning, by a massive surplus of water. On the one hand, TEPCO (“The Sorcerer’s Apprentice”) pumps in 400 tons of fresh water daily to cool the corium. On the other hand, groundwater presses upwards with estimated 300 tons daily through cracks into the basement of the plants. The seawater wall will increase the water accumulation by retaining groundwater. All the mixed sea, fresh and ground water in the basements and below is highly toxic and must be pumped up and out to avoid a radioactive swamp site. Additionally, TEPCO pumps uphill groundwater to reduce the flow. The storage capacity at the reactor site is nearly exhausted and TEPCO is overwhelmed by problems.

But there is one advantage in the situation that seems a problem at first sight: the groundwater pressure prevents the uncontrolled outflow of toxic water through the cracks. At the moment, we merely see a slow diffusion of toxic elements within the water mix rather than a fast active transport. The most toxic layers can still be pumped up. Thus, if you remove the groundwater pressure, all basements and tunnels will suck dry by gravity and the entire toxic cooling water enters the environment without a chance of retaining it. From this point of view, the groundwater pressure is not a problem, but on the contrary, favorable.

The proposal is:

1. Separate the water storage and treatment from the decommissioning and cooling of the reactors. Build a pipeline to a distant region such as Rokkasho, where there is plenty of space, knowledge, adequate facilities and the chance for experimental cleaning such as ALPS, SARRY or newer concepts. This can’t be done by TEPCO at the Fukushima site. The disaster is a national task. A pipeline is cheap, viable and well-established technology. If a pipeline becomes impossible a new facility in a safer location should be established with similar waste capability to Rokkasho. The evacuation zone may contain a potential candidate site. It should be possible to transport wastewater for example in safe casks on trucks. There is no real need to store it at Fukushima under those obviously insufficient circumstances and supervision by Tepco.

2. Instead of stopping the groundwater, increase its viscosity gradually. In this way the pressure can be kept up while a separation of fresh and toxic water layers can be achieved. With increasing viscosity also a certain grade of basement sealing could be accomplished without the difficult necessity to first find and evaluate the leaks. Let the water do it.

The use of various injected viscous (gelatinizing, colloid) agents have been used in the industry to slow down ground water flows. Using a series of partly already existing upstream wells (green in the diagram), water could be extracted, mixed with the viscous agents then re-injected back into the upper groundwater layers. In this way, the flow of groundwater can be utilized as transporting mechanism. It would cause the flow of water to slow yet still keep geologic features filled and buoyant.

This proposal could be a non-costly and relatively environment-neutral solution.

Governance And Oversight

These efforts are al likely outside of the scope of TEPCO’s capabilities and finances. This type of work still must be done to prevent further international contamination and needs to be done in an expedient manner. This can not wait for elections, budget years or other political maneuverings. Currently the Japanese government is reluctant to deal with it, TEPCO can’t, the IAEA and US DOE are willing to offer expertise but the ability take responsibility and lead has been lax. Someone must be the adult in the room and do something other than watching Daiichi leak into the sea for decades. Researchers found that the plant is still leaking, is creating hot spots on the sea floor and has already contaminated Pacific fish to varying degrees. What they don’t know is exactly what will happen over time and how widespread the contamination will end up.

Such projects will take considerable engineering and manpower, not to mention money but it needs to be done to contain the disaster and to allow work to continue at Daiichi. Important work at the plant still lies ahead. Fuel must be removed from the spent fuel pools. Melted reactor cores need to be located and secured. For this to happen someone must take charge.

Since the admission by TEPCO that the plant has been leaking for the last 2+ years and that it continues to leak, there has been much international concern. Daiichi has massive amounts of groundwater passing through the plant grounds every day. The ground water is seeping into the reactor buildings and is becoming contamination with radioactive contamination. This is something no other nuclear site has had to deal with related to contamination or a meltdown. Fukushima differs greatly from both Hanford and Chernobyl, the two sites most frequently compared to the problem in Japan.

Since the admission by TEPCO that the plant has been leaking for the last 2+ years and that it continues to leak, there has been much international concern. Daiichi has massive amounts of groundwater passing through the plant grounds every day. The ground water is seeping into the reactor buildings and is becoming contamination with radioactive contamination. This is something no other nuclear site has had to deal with related to contamination or a meltdown. Fukushima differs greatly from both Hanford and Chernobyl, the two sites most frequently compared to the problem in Japan.

No comments:

Post a Comment